RFID

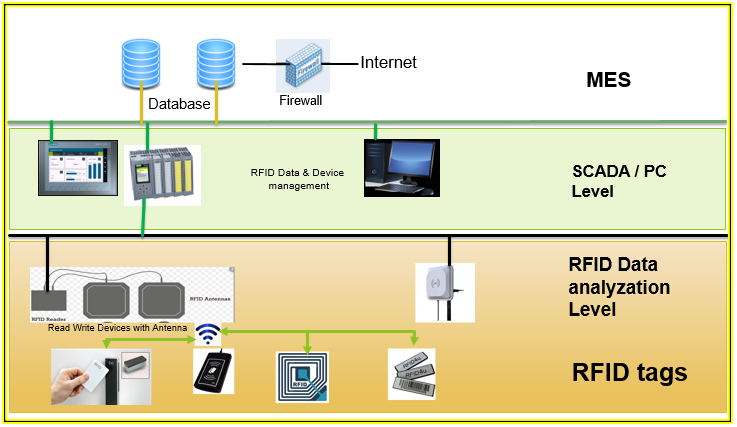

RFID belongs to a group of technologies referred to as Automatic Identification and Data Capture(AIDC). AIDC methods automatically identify objects, collect data about them, and enter those data directly into computer systems with little or no human intervention and stores the data in a database and analyzed at a later time.

- Traceability: RFID tracks the product across the different segments of production and supply chain from source to destination to optimize the control.

- Press Shop Tool Identification: An automatic identification system using RFID prevents errors for tool insertion and provide proper functioning.

- Paint Shop Skid Identification: RFID system avoid production errors and provide reliable identification of skid in the paint shop through the entire process.

- Body Detection in Production: RFID system provide the current location of individual vehicles in entire production with the help of an RFID tag.

- Inventory Management: To manage the products in the retail store as per regular and planned production by using an RFID tag.

- Identification of Test Bottles: Detection of the test bottles and replace them with new bottles with continuous monitoring.

- Detection of Goods Container: RFID is used to ensure the material flow and container’s current location in the process line.

- Reverse Engineering Analysis: Reverse engineering and improper functioning in the system cycle can be easily identified with the RFID stored database and analyzation.