Training

To boost the value of an Individual for self & Organization Development. We Conduct training programs for Fresh Engineers / Working Professionals / End Users.

"VOICE of Industry" is - Lack of trained Professionals / Fresh Engineers as per Industry requirement. Engineering Institutes results are touching Sky. We try to fill the GAP between Industrial requirement and the Technical skill of the candidate by “Re-Engineering”.

Training and Development help in Optimizing the utilization of the human resource, increasing the job knowledge and skills of employees at each level, that further helps to expand the horizons of the human intellect, overall personality development of the employees. So the employees can achieve the Organization goals as well as their individual goals.

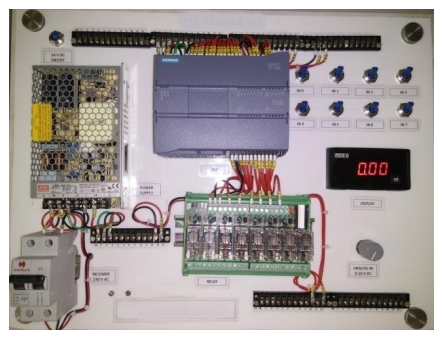

We undertake training services for Customized & trainings based on installation platforms and specific demands of contents and schedules. These hands-on training help the customer for routine maintenance and reduction in downtime.

Training Program:

- Identification of control inputs & outputs.

- Hardware control & control through PLC.

- PLC Architecture.

- Selection of PLC.

- Interfacing control I/O’s to PLC.

- Basic Ladder Logic Instructions, Contact, coils & PLC scan.

- Control using various control instructions like timer, counter, math, etc.

- Analog control and Data handling.

- Downloading & Uploading of PLC program.

- Communication Protocol and configuration.

- Troubleshooting.

- Practical Exercises.

- Need, Operation & Fundamentals of HMI.

- Types of HMI.

- HMI specification & selection criteria.

- Various setting from HMI.

- Interfacing with PLC.

- Project development-Screens & configuration.

- Defining tags.

- Recipe, Alarms, Security.

- Communication Protocols.

- Transferring project to HMI.

- Troubleshooting.

- Practical Exercises.

- Principle of 1Ø & 3Ø Motors.

- DOL & Star/Delta starter.

- Power devices – Thyristors & IGBTs.

- Single & Four Quadrant Application.

- Speed Control & Torque-Tension mode.

- Winding – Unwinding application.

- Complicated application – Close loop with PID.

- Diameter calculation for winder-unwinder.

- Communication with PLC.

- Troubleshooting.

- Practical Exercises and Demonstration.

- DC DRIVES (Analog and Digital).

- DSC control system architecture.

- System configuration introduction.

- DCS system hardware configuration.

- DCS system logic development.

- DCS system graphics development.

- DCS system logic and graphics integration introduction.

- DCS system logic and graphics simulation.

- DCS system hardware engineering.

- DCS system networking & configuration.

- DCS system & third party system communication.

- Introduction to SCADA.

- Need, Concept & Basic features of SCADA.

- Configuration of different drivers.

- Database of Tags & it’s use.

- Graphic Screens – Concept & need.

- Interfacing with PLC and Interfacing simulation of PLC application.

- Digital & Analog supervision through Graphic Screen.

- Digital & Analog control through Graphic Screen.

- DATA Acquisition and Report generation through SCADA.

- Messages & Alarms.

- Troubleshooting.

- Practical Exercises.

- AC & DC power supply.

- CT, PT & Isolation transformers.

- AC & DC load connections in electrical.

- Measuring devices-Multimeter, Tester.

- Load calculation - series & parallel loads Front panel logics.

- Devices on the panel for user interface.

- Control using switching contacts – NO/ NC and its Configuration.

- Positive & negative switching & ascertaining o/p voltage Relay & Contactor logic.

- AC/DC Relays - Load control application.

- Contactors for load control – Power & auxiliary Switchgear & Control.

- Switchgear-operation, Control & Selection.

- MCB, MCCB, ELCB, MPCB, SFU, OLR AC Motor & Starters (DOL and Star/Delta).

- Selection of components as per rating of Motor & Heater application.