Service

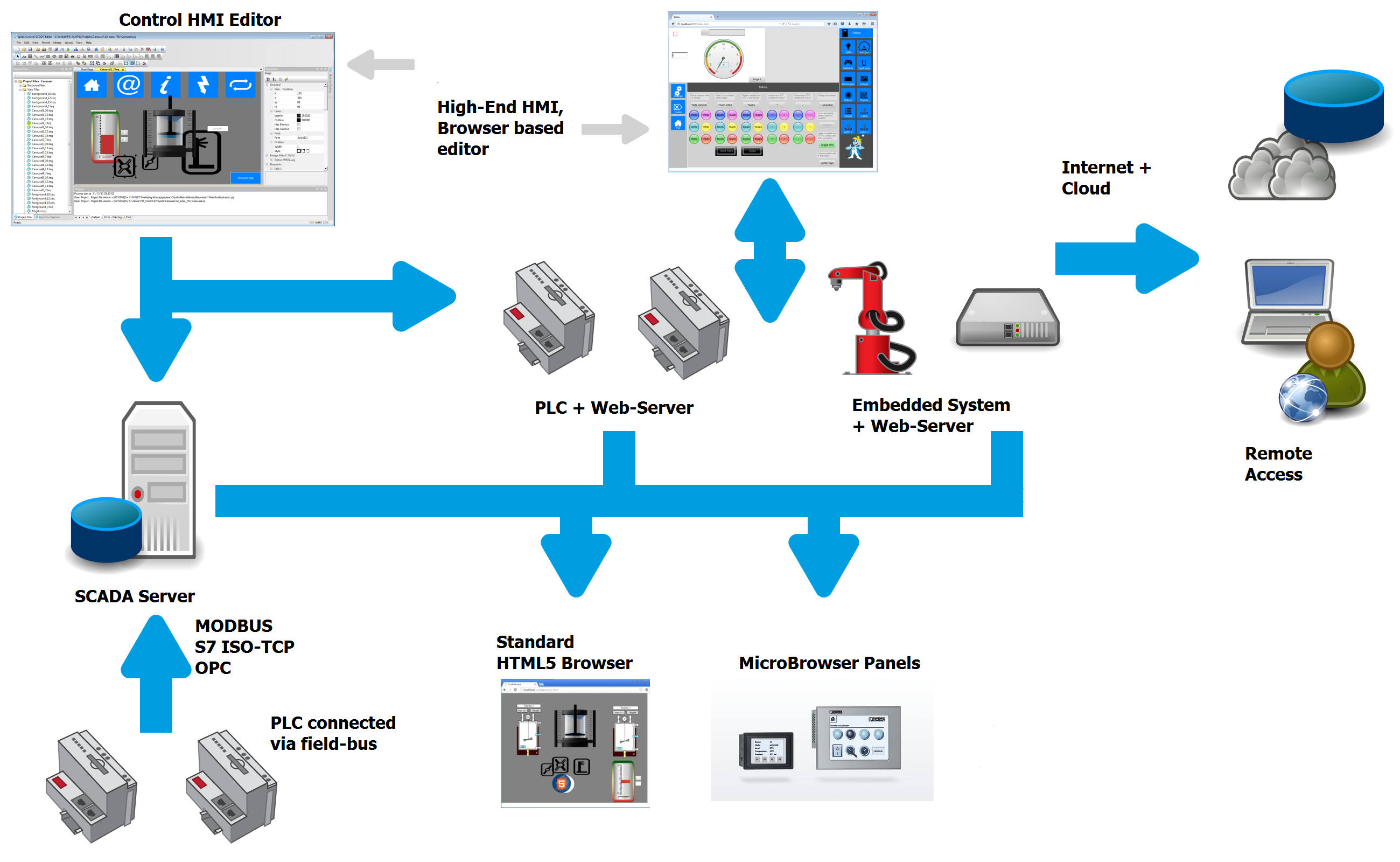

Software Development

Our team brings advanced technology & expertise across multiple PLC/DCS control system platforms & Industrial domains. Our control team experts help, optimizing PLC/DCS programming standards and coding techniques to ensure reduced complexity, optimal performance, easy integration, and greater expandability. Our team works on Siemens, Rockwell, Honeywell, Mitsubishi, Delta, Schneider, Omron PLCs/ HMI platforms using programming languages Ladder, FBD, STL, SFC, ST, GRAPH.

- Profinet.

- Profibus.

- Ethernet TCP/IP.

- Ethernet/IP

- CC-Link

- DeviceNet

- ControlNet

- DH+

- IO-Link

- Modbus

- OPC

- Vision

- Bar code scanners

- Printers

- RFID & Other many devices

- SQL

- .NET

- Visual Basics

COMMUNICATION PROTOCOLS:

3rd PARTY INTEGRATION:

IT SOLUTIONS:

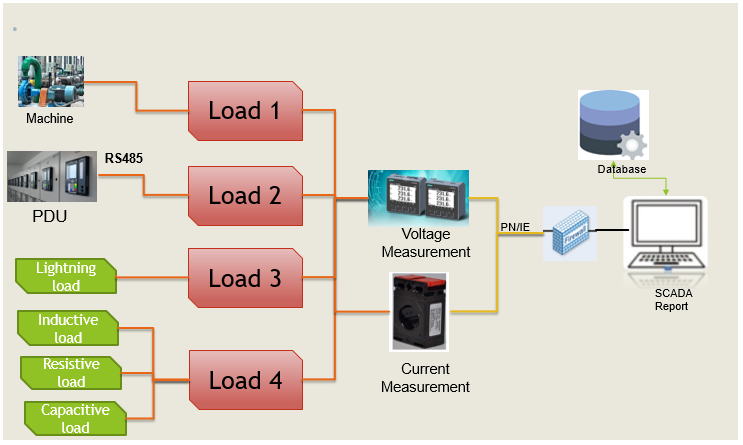

We help manufacturing companies embrace digital manufacturing Platforms by interfacing shop floor level PLCs and control systems to IIOT sensors, devices, and databases. We can bridge the gap between legacy PLC based manufacturing platforms and IOT by working with proprietary protocols, standards, and 3rd part devices Hardware & Software FAT support.

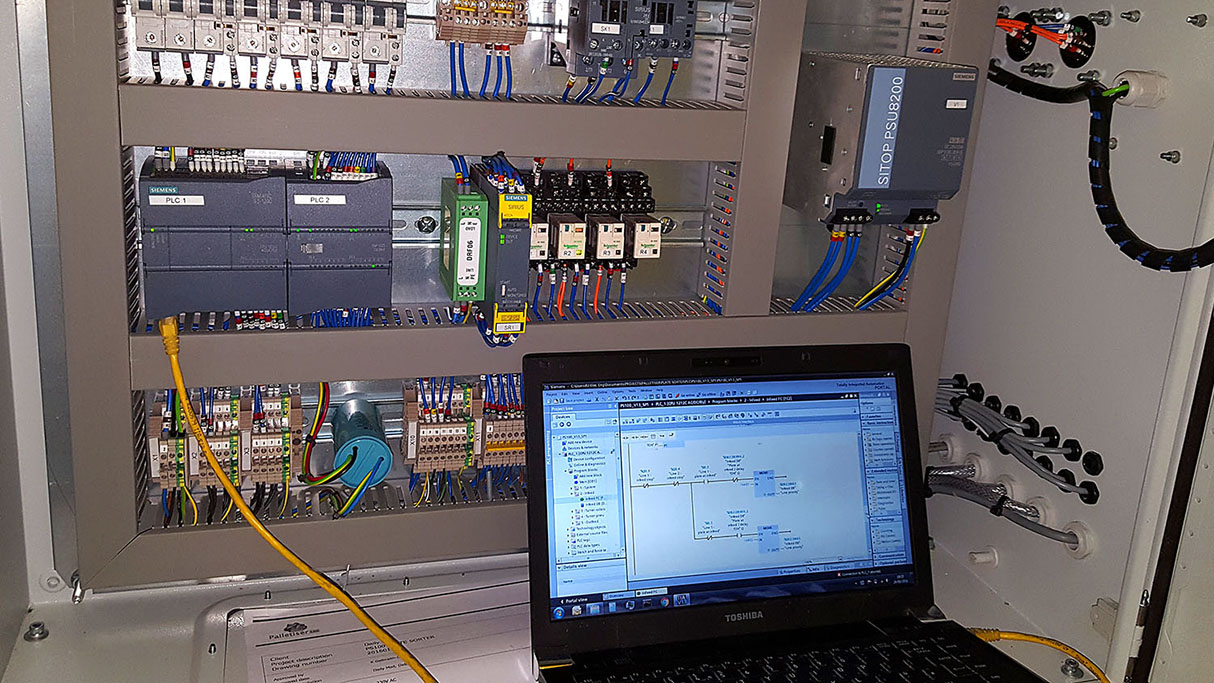

Installation & Commissioning

- PLC, DCS automation project site installation supervision

- Panel Erection support

- Installation field-wiring & termination.

- Cold loop Hot loop testing

- Calibration of loops

- Commissioning supports

- SAT & Project documentation Handover

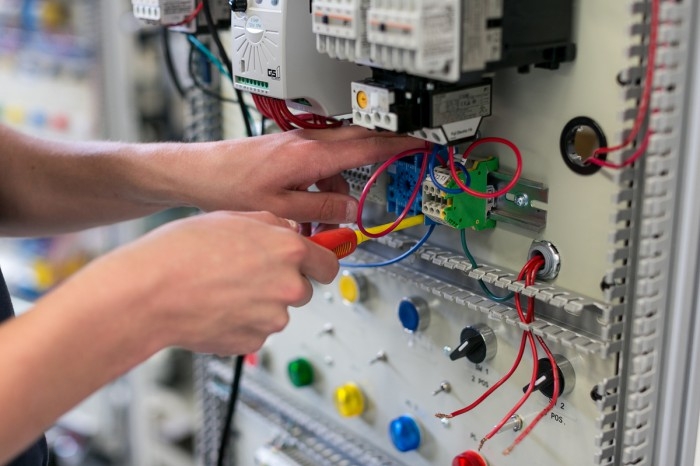

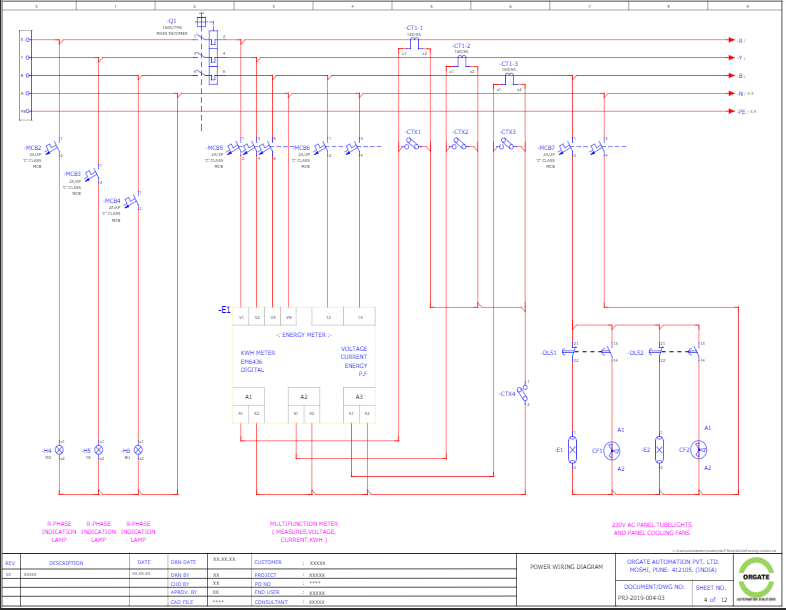

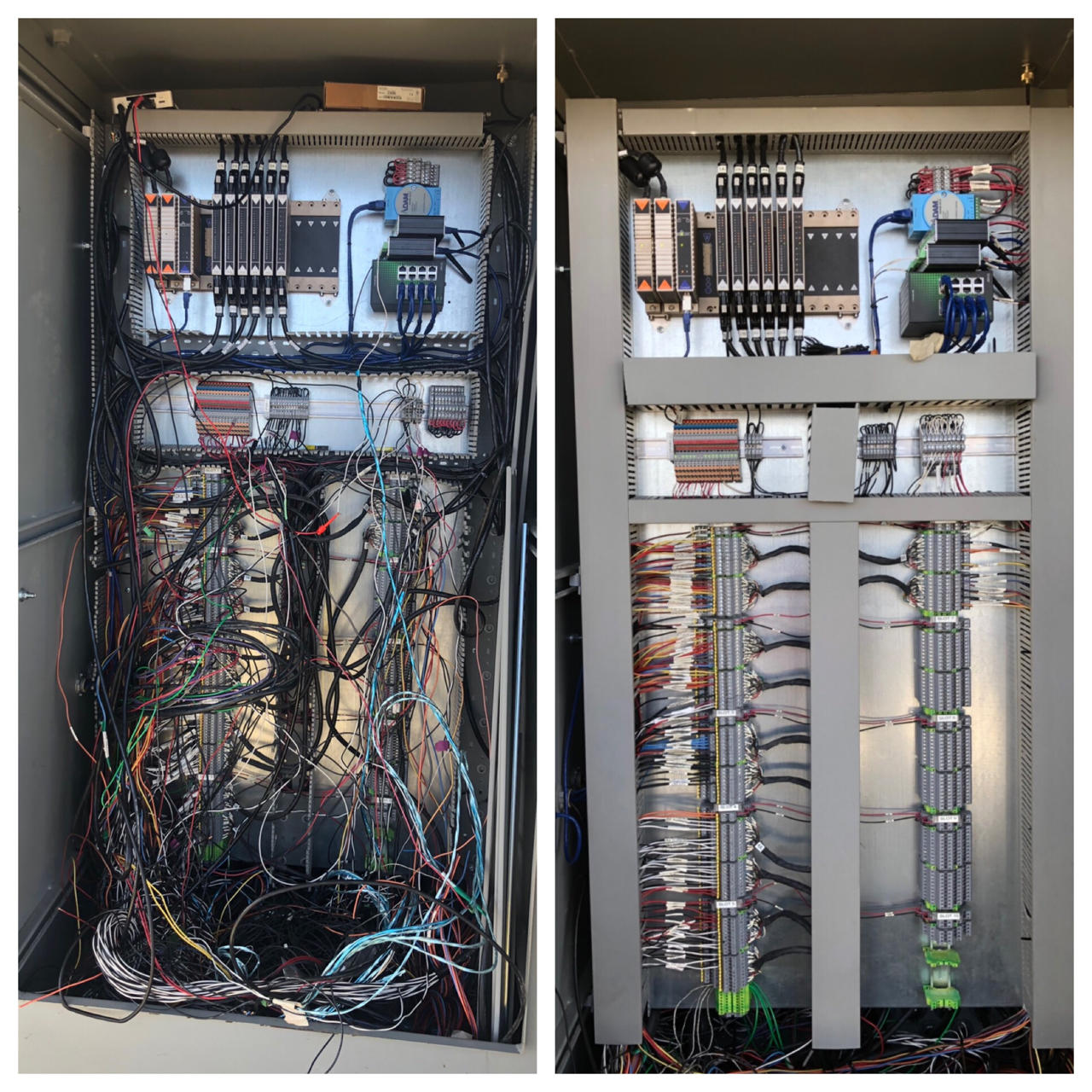

Electrical Panel Manufacturing

We have a manufacturing facility and a dedicated team for manufacturing of:

- PLC Control Panels

- MCC (Motor Control Centre) Panels

- PDB (Power Distribution Board)

- PCC (Power Control Panel)

- VFD panels

We provide end to end solution, implementation, and support which includes:

- Electrical design & development

- Control panel manufacturing

- Consulting

- Commissioning support

- Implementation & onsite support

- Product training

Electrical Designing

- We have a dedicated team of design engineers for designing control panels, MCC (Motor Control Centre), PDB (Power Distribution Board), VFD panels, etc.

- Based on customer inputs, we design panel GA (General Arrangement) drawings, internal panel layouts, and detailed wiring drawings.

- Digitalization of old panels (Drawing preparation of old Panels from hardcopy/Control Panel)

- Upgradation of old Relay/Contactor logic to PLC.

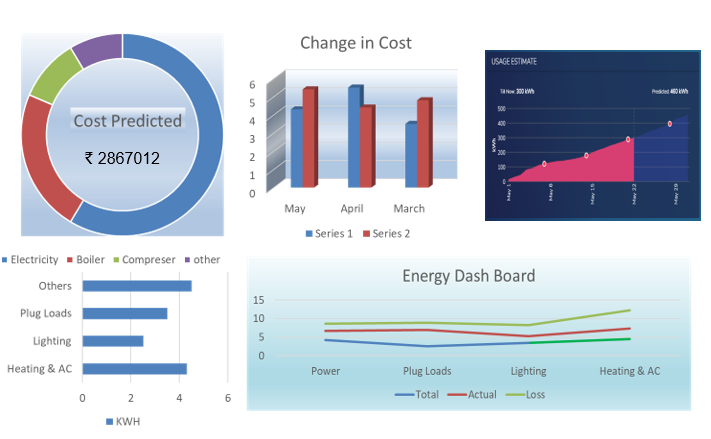

Energy Management

An ideal energy management solution for industries, manufacturing plants, commercial buildings, malls, or other applications where a high amount of energy is consumed by giving user control & management features. Generation of analytical graphs & reports.

- Avoid excess demand charges.

- Lessen the impact of utility power outages.

- Eliminate power factor penalties.

- Automatically control on-site generation.

- Faster data collection.

- Operating Equipment Efficiency.

- Usage-Based Cost Accounting.

- Load Profiling, Consumption Reporting.

- Demand Analysis, Shadow Billing.

- Power Quality.

- Electrical Distribution layout system.

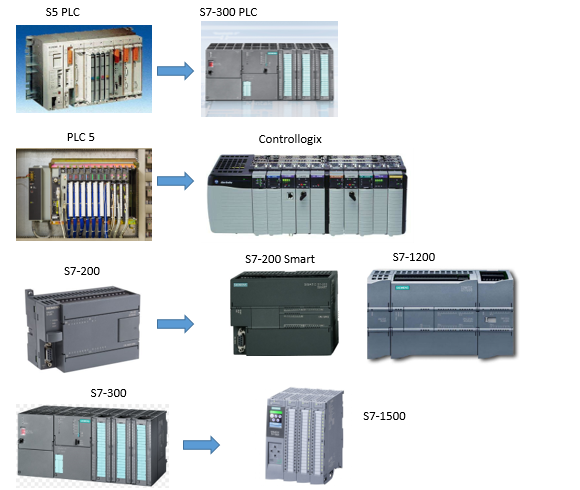

Migration of Control System

Our engineers are familiar with Siemens, Allen-Bradley, Honeywell, Mitsubishi, Delta, Schneider, Omron, and other manufacturers. On PLC/HMI/Drive migration projects, we will work as per customer requirement to upgrade the original schematics, convert the existing Logic/Graphics to the new platform and fully test the control system once installed.

Why Migration Require:

- It gets harder and harder to find qualified service and maintenance staff. Partly, as a result, the maintenance budgets get higher every year.

- Because of the fact the old system is no longer supported, there is a lot of work in maintenance and repairs.

- In some cases, the old system does no longer meets the production capacity and product quality that companies try to achieve.

- The old system has low memory space which does not support the addition of I/O modules in the system.

Migrated systems:

- Migration S5 PLC Series to S7 PLC Series

- Migration S7-300 to S7-1500 PLC

- Migration of S7-200 to S7-200 Smart/S7-1200.

- Migration PLC5 to ControlLogix and IO conversion

- Migration DH+ to Ethernet IP

- Migration DeviceNet to Ethernet IP

- Migration Profibus to Profinet

- Migration of RIO

- Migration of HMI & SCADA systems

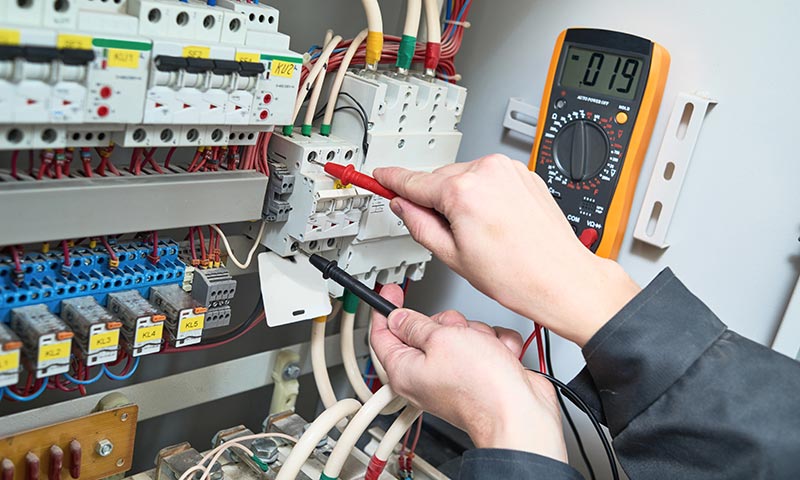

Control Panel Retrofitting

Upgrade from an existing level control to a new level control device. Evaluation of an existing system relative to various state and local codes.

- Evaluation of existing system and existing documents.

- Clear determination of the anticipated new retrofit configuration and subsequent control and operational parameters.

- Design control panel layout & wiring diagrams.

- Manufacture, delivery, install, and start-up of the new retrofit configuration.

- Provide O&M documentation, training, and warranty.

- On-site evaluation of existing problems

- Determine if the problem can be repaired onsite during the evaluation visit.

- Upgrade Relay/Contactor logic to New control system logic.

Repairs & Service Centre

- Drives (AC-DC Drives)

- PLC Systems

- Human Machine Interface (HMI)

- Power Supply